Solidzer 450 Pro

Sintertek's Layered Laser Fusion Technology represents the pinnacle of additive manufacturing solutions, delivering unique performance and production rate, tolerance, durability and surface quality.

Sintertek's Layered Laser Fusion Technology represents the pinnacle of additive manufacturing solutions, delivering unique performance and production rate, tolerance, durability and surface quality.

Solidzer machine platform developed specifically for layered fusion technology provides

the user with simplified interface and efficiency improving features.

Products manufactured have competing properties to injection molding technology these parts can be build without any molds or tools. these parts can be built at the same time even, when each part differs from each other.

Solidzer with it’s digital laser scanner, absolute positioning sensors, servo motors and heat treated block frame will keep it’s consistent output for many years to come.

Building box can be stacked with hundreds of different parts and all these parts will be manufactured at once even if they are on top of each other. Thanks to this ability user can optimize and speed up their manufacturing schedule.

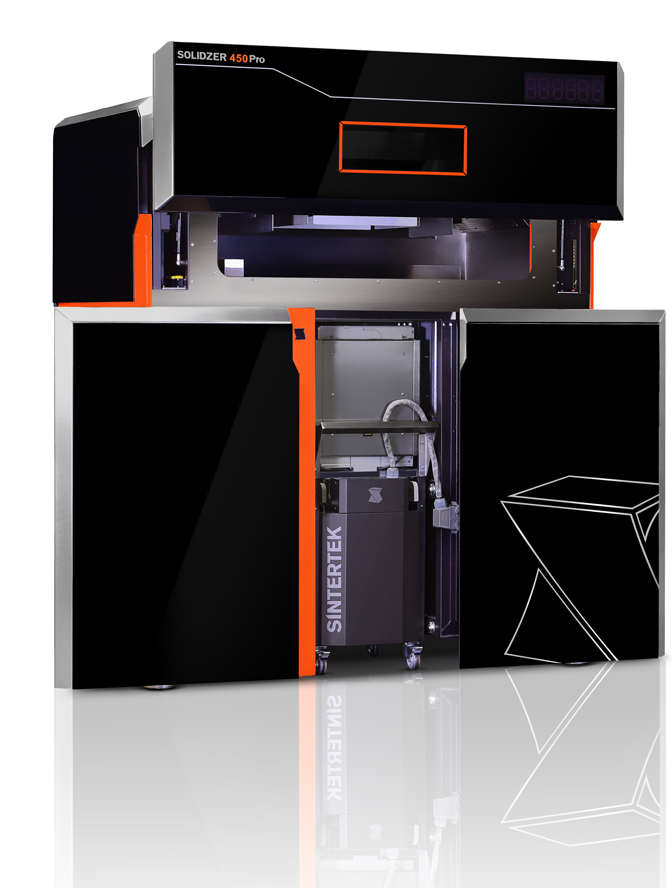

Solidzer 450Pro’s reduces the cooling and warm up times of the production up to 75% thanks to it’s modular building area and advanced thermal sensors.

Our hardware, software, materials and services were designed together

to enable the continual improvement of our products while delivering

a seamless printing experience.

Open system, adjustable parameters

Local heat control with image processing system

Opportunity to use required raw material

Prevention of temperature strain with controlled cooling

Continue to production with new building box during the cooling phase

Build in inert gas generation and vacuum pump

In cooling phase, the modular building box will cool off

computer aided and it minimize thermal distortion. At

this time, the new building box can be placed and print

continued without waiting for the cooling phase.

330

mm330

mm450

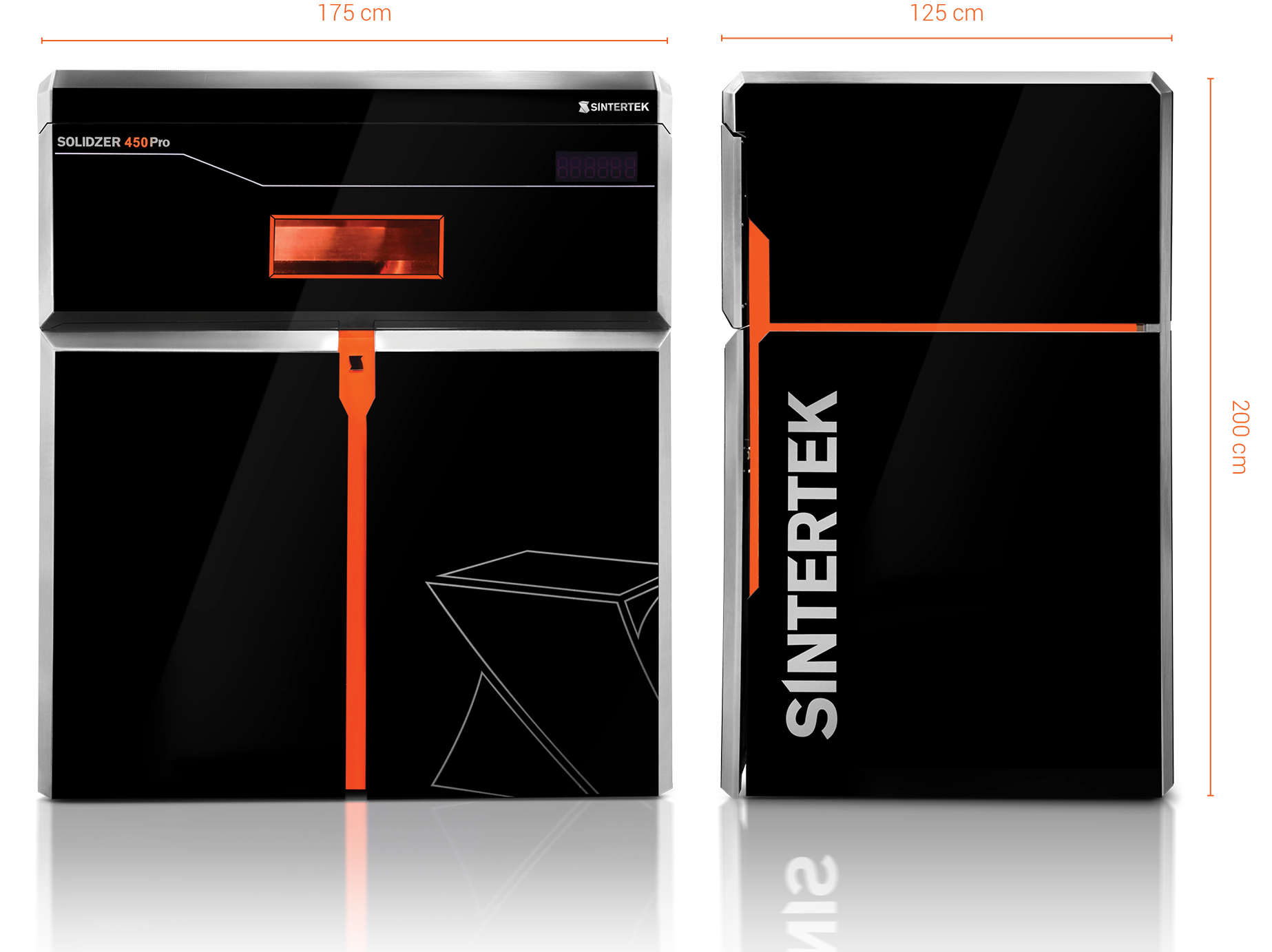

mmTechnical Data Solidzer 450 Pro

350mm x 350mm x 450mm

310mm x 310mm x 430mm

30mm/h

60 µm - 150 µm

70W / CO2

10m/s

3.5kW normal, 10kW maximum

32A 380V 3 Faz

6bar 100lt/dk

Integrated

SolidzerGO,ReportMaster

Dimensions

200cm x 175cm x 125cm

250cm x 350cm x 300cm

1400kg